Our areas of expertise

We create sustainable solutions for the future

Our knowledge and expertise are well documented. At Matenco, we are driven by offering services and products that not only make our customers happy, but also challenge old ways of thinking. We want to streamline and invent new ways to create sustainable societies.

We take care off the entire process from start to finish

Choosing Matenco is choosing a partner. You don’t have to deal with any subcontractors, we make sure that the job gets done and you get satisfied, and only have to deal with us.

40 years of experience and still evolving

Our roots have shaped us. A family-owned company that grown from a small industry in Skogås, to one of the leaders in Sweden. Every client we have partnered up with always comes back, that to us is what makes this so fun. We strive to challenge ourselves, and continue our growth, while we want to keep our core and the reason why we started doing this from the beginning.

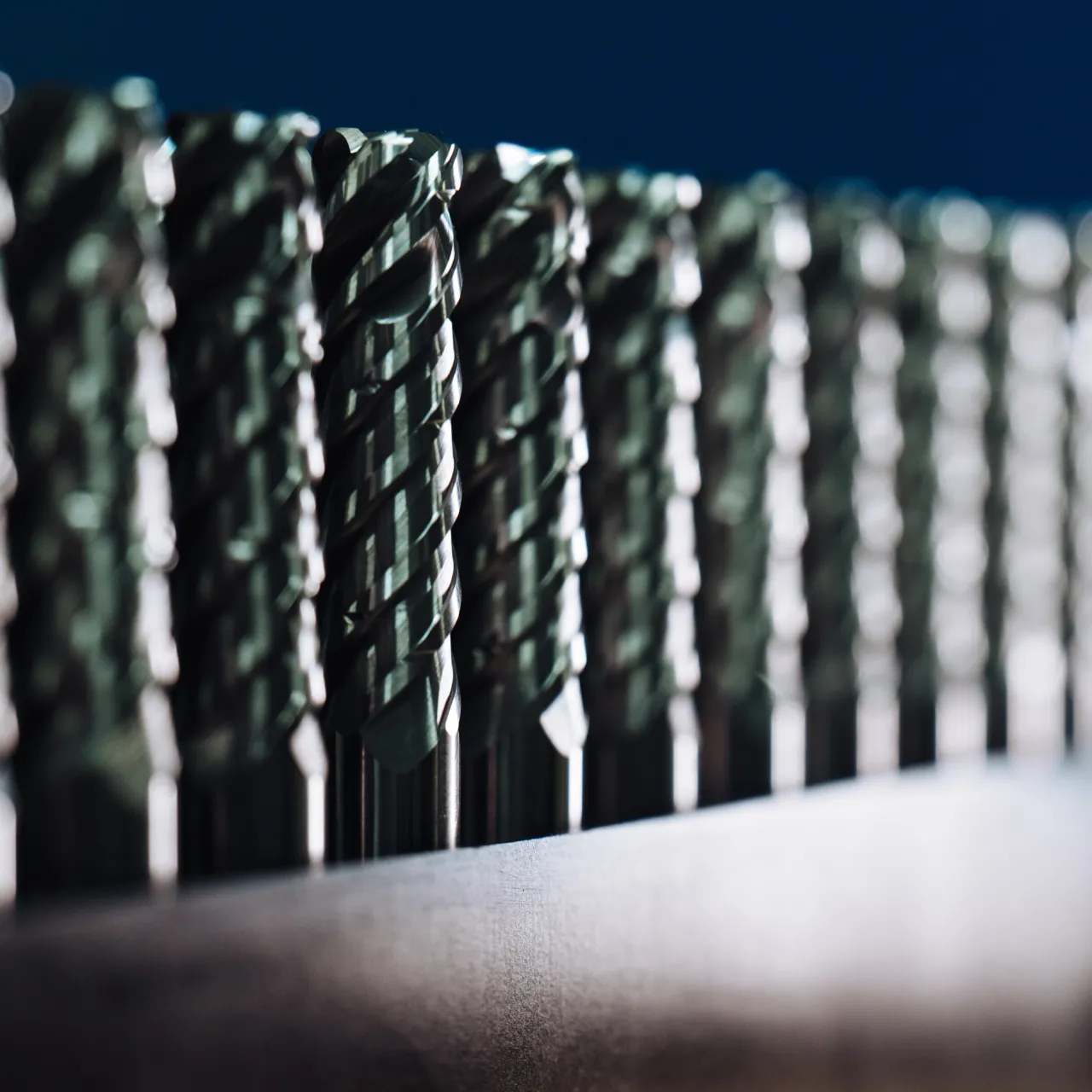

CNC Machining

Our expertise within CNC Machining is what we are known for. Our machine park is developed so that we quickly can select the most suitable machine to handle the task.

Wire EDM

Wire EDM is an innovative and revolutionary cutting method in CNC machining. Regardless of the hardness of the lead metal, Wire EDM cuts through the desired material. We use wire EDM for various industries, from the pharmaceutical industry to the compressed air industry.

Assembling

Sometimes products and components need to be supplemented with additional products. We assist with both parts. Either if you need any other product or feature that can complement your desires, or if you know that you only need a minor part of something bigger.

Burnishing

Polishing of metals often does so in terms of aesthetic reasons. Especially when it comes to the car industry. The importance of the shiny, mirror-like surface can be decisive in how an impression is treated.

Lapping

If burnishing or turning not does the job for that perfect surface smoothness, lapping is preferable. Repeated movements of polishing tools create a light pressure on the part being machined.

Trumbling

The method rarely requires the supervision of an operator, which makes the process cost-efficient. Our process is, as always, meticulous. To further ensure the high quality of our production, we document our process and follow our high-quality guidelines.

Laser Marking & Engraving

We have high-quality laser marking machines to laser mark the logo, article number, etc., according to the customer’s requirements. We have extensive experience in engraving and laser marking all possible materials and we always ensure that the quality is as high as possible.

Collaboration

Matenco broadens its service offerings through strategic collaborations, enhancing our capabilities to deliver an extended suite of manufacturing solutions. Our commitment to precision and excellence is strengthened by these partnerships, allowing us to cater to diverse client needs.

Micromatic

Micromatic is a contract manufacturer of complex products with high precision requirements. We boast an advanced machinery fleet with cutting-edge 5-axis machines that lead the market in machining capabilities.

Naverviken

Naverviken excels in assembling complex structures and manufacturing components, specializing in stainless steel and aluminum. Our operations also include contract manufacturing of details across materials, supported by advanced 5-axis machines.

Detailed precision for innovative industries

By combining our detail-oriented craft with innovations of tomorrow, we produce results that change people’s lives.

We are experienced

Over 40 years of experience in CNC-manufacturing

We are secure

Over 40 years of experience in CNC-manufacturing

We are more than a supplier

Over 40 years of experience in CNC-manufacturing

Join us

As a leading player in the industry, we take pride in our commitment to excellence and cutting-edge technology. We're on the lookout for passionate and skilled individuals who share our vision for pushing the boundaries of what's possible.

Let’s talk

Whether you have specific questions about our products, want to discuss a potential collaboration, or simply need more information, our team at Matenco is here to help.

Contact us

Fill out the form and a member of our team will reach out to you.

Jordbrotorpsvägen 2

136 50 Haninge